قیمت لوله و اتصالات پلی پروپیلن 1404/11/28 بزرگترین تولید کننده لوله پلی پروپیلن

اردیبهشت 17, 1400

منهول پلی اتیلن 1404/11/28 قیمت تولید کننده منهول پلی اتیلن

خرداد 3, 1400

PE pipe

Polyethylene pipe or PE Pipe is a type of pipe made of polyethylene polymer. Polyethylene is one of the most widely used polymers in the industry, which is used to make water, sewage, gas, oil, irrigation, etc. pipes due to its superior physical and mechanical properties. According to the manufacturing method, polyethylene pipes can be produced in two different types, namely high pressure polyethylene pipe (HDPE) and low pressure polyethylene pipe (LDPE). In these two types of pipes, polyethylene is used with different values of density and molecular weight, which are selected for each specific application. Due to its properties such as lightness, high resistance to impact, pressure, corrosion, wear and tear, as well as the lack of UV rays, polyethylene pipe is used in various environmental conditions, including areas with soft soils and prone to earthquakes, industrial and commercial environments, gardens. It is suitable for agriculture, mining, etc.

The price of polyethylene pipe

The price of polyethylene pipe. We provide you with the most complete list of pipe prices along with its equipment and accessories, updated every day. Due to the fluctuations in the price of polyethylene raw materials, as a result, the price of polyethylene pipe is not fixed and changes every day, and in relation to the market situation, we are doing our best to increase the price of polyethylene pipe and We will update all the accessories and polyethylene pipe connections every day and make them available for you to download. It is better to contact the factory consultants to confirm the price. We will carefully consider your price request. The price of polyethylene pipes is calculated based on various factors such as size, wall thickness, resistance to pressure, type and quality of raw materials, brand and manufacturer, place of production and sale, and other market conditions. Rotengaran Parse is one of the largest producers of polyethylene pipes in the Middle East in the variety of PE 100 and PE 80 pipes with the most advanced equipment and production lines in the world along with an equipped laboratory and scientific and experienced staff ready to cooperate with colleagues and respected buyers of the products. It is self-produced. To buy and to know the exact price of the day and sales conditions of the products, contact the sales managers of the company. Note that the price of non-standard and grade 2 pipes can be 4% lower than the listed prices of grade 1.

What does the purchase of polyethylene pipe depend on?

The purchase of polyethylene pipe depends on the diameter and pressure of the pipe as well as its raw materials, and these types of pipes come in different diameters, which usually start from 20 mm and finally lead to 3200 mm in huge designs. The pressure of pipes depends on its uses, the higher the pressure, the higher its strength. Polyethylene pipe standards are diverse and are categorized in agricultural, water supply, gas and sewage applications. If you do not know enough about the variety of polyethylene pipes, we will be happy to help you choose the best and most suitable pipe. The group of sales managers of Rotenganar Parse factory complex is ready to advise you dear ones. The diameter of 3200 mm is exclusive to Rotengaran Parse polyethylene pipe factory, contact us to know the price and receive advice.

Download the polyethylene pipe price list

The price of polyethylene pipe

Polyethylene pipe – sewage – construction 4 times

Installment sale with bank guarantee

The price of polyethylene sewage pipe – constructionGrade A PE100 The standard and approved seal of Jihad Agriculture Water and Soil Company |

|||

| 4 bar polyethylene sewage pipe | Price per meter | thickness | Weight |

| PE pipe 63 sewer 4 bar | 183,000 IRR | 1.8 Mm | 0.364 |

| PE pipe 75 sewer 4 bar | 235,000 IRR | 2.0 Mm | 0.467 |

| PE pipe 90 sewer 4 bar | 324,000 IRR | 2.2 Mm | 0.643 |

| PE pipe 110 sewer 4 bar | 476,000 IRR | 2.7 Mm | 0.943 |

| PE pipe 125 sewer 4 bar | 621,000 IRR | 3.1 Mm | 1.23 |

| PE pipe 140 sewer 4 bar | 777,000 IRR | 3.5 Mm | 1.54 |

| PE pipe 160 sewer 4 bar | 1,010,000 IRR | 4.0 Mm | 2.0 |

| PE pipe 180 sewer 4 bar | 1,257,000 IRR | 4.4 Mm | 2.49 |

| PE pipe 200 sewer 4 bar | 1,540,000 IRR | 4.9 Mm | 3.05 |

| PE pipe 225 sewer 4 bar | 1,949,000 IRR | 5.5 Mm | 3.86 |

| PE pipe 250 sewer 4 bar | 2,439,000 IRR | 6.2 Mm | 4.83 |

| PE pipe 315 sewer 4 bar | 3,797,000 IRR | 7.7 Mm | 7.52 |

| PE pipe 400 sewer 4 bar | 6,110,000 IRR | 9.8 Mm | 12.1 |

| PE pipe 450 sewer 4 bar | 7,726,000 IRR | 11.0 Mm | 15.3 |

| PE pipe 500 sewer 4 bar | 9,595,000 IRR | 12.3 Mm | 19.0 |

| PE pipe 560 sewer 4 bar | 11,918,000 IRR | 13.7 Mm | 23.6 |

| PE pipe 630 sewer 4 bar | 15,099,000 IRR | 15.4 Mm | 29.9 |

| PE pipe 710 sewer 4 bar | 19,190,000 IRR | 17.4 Mm | 38.0 |

| PE pipe 800 sewer 4 bar | 24,290,000 IRR | 19.6 Mm | 48.1 |

| PE pipe 900 sewer 4 bar | 30,754,000 IRR | 22.0 Mm | 60.9 |

| PE pipe 1000 sewer 4 bar | 37,976,000 IRR | 24.5 Mm | 75.2 |

PE pipe agriculture 6 bar

price of PE pipe agricultureGrade A PE100 The standard and approved seal of Jihad Agriculture Water and Soil Company Installment sale with bank guarantee |

|||

|

PE pipe agriculture 6 bar |

Price per meter |

thickness | Weight |

| PE pipe 63 agriculture 6 bar | 249,000 IRR | 2.22 Mm | 0.494 |

| PE pipe 75 agriculture 6 bar | 341,000 IRR | 2.9 Mm | 0.675 |

| PE pipe 90 agriculture 6 bar | 493,000 IRR | 3.5 Mm | 0.978 |

| PE pipe 110 agriculture 6 bar | 722,000 IRR | 4.2 Mm | 1.43 |

| PE pipe 125 agriculture 6 bar | 929,000 IRR | 4.8 Mm | 1.84 |

| PE pipe 140 agriculture 6 bar | 1,171,000 IRR | 5.4 Mm | 2.32 |

| PE pipe 160 agriculture 6 bar | 1,535,000 IRR | 6.2 Mm | 3.04 |

| PE pipe 180 agriculture 6 bar | 1,913,000 IRR | 6.9 Mm | 3.79 |

| PE pipe 200 agriculture 6 bar | 2,368,000 IRR | 7.7 Mm | 4.69 |

| PE pipe 225 agriculture 6 bar | 2,974,000 IRR | 8.6 Mm | 5.89 |

| PE pipe 250 agriculture 6 bar | 3,686,000 IRR | 9.6 Mm | 7.3 |

| PE pipe 315 agriculture 6 bar | 5,858,000 IRR | 12.1 Mm | 11.6 |

| PE pipe 400 agriculture 6 bar | 9,393,000 IRR | 15.3 Mm | 18.6 |

| PE pipe 450 agriculture 6 bar | 11,867,000 IRR | 17.2 Mm | 23.5 |

| PE pipe 500 agriculture 6 bar | 14,594,000 IRR | 19.1 Mm | 28.9 |

| PE pipe 560 agriculture 6 bar | 18,281,000 IRR | 21.4 Mm | 36.2 |

| PE pipe 630 agriculture 6 bar | 23,179,000 IRR | 24.1 Mm | 45.9 |

| PE pipe 710 agriculture 6 bar | 29,492,000 IRR | 27.2 Mm | 58.4 |

| PE pipe 800 agriculture 6 bar | 37,319,000 IRR |

30.6 Mm | 73.9 |

| PE pipe 900 agriculture 6 bar | 47,167,000 IRR | 34.4 Mm | 93.4 |

| PE pipe 1000 agriculture 6 bar | 58,075,000 IRR | 38.2 Mm | 115 |

PE pipe agriculture 10 بار

Price PE pipe agricultureGrade A PE100 The standard seal and approval of Jihad Water and Soil Company agriculture Installment sale with bank guarantee |

|||

|

PE pipe Water supply 10 bar |

Price per meter |

thickness | Weight |

| PE pipe 63 Water supply 10 bar | 364,000 IRR | 3.8 Mm | 0.721 |

| PE pipe 75 Water supply 10 bar | 515,000 IRR | 4.5 Mm | 1.02 |

| PE pipe 90 Water supply 10 bar | 737,000 IRR | 5.4 Mm | 1.46 |

| PE pipe 110 Water supply 10 bar | 1,096,000 IRR | 6.6 Mm | 2.17 |

| PE pipe 125 Water supply 10 bar | 1,393,000 IRR | 7.4 Mm | 2.76 |

| PE pipe 140 Water supply 10 bar | 1,747,000 IRR | 8.3 Mm | 3.46 |

| PE pipe 160 Water supply 10 bar | 2,282,000 IRR | 9.5 Mm | 4.52 |

| PE pipe 180 Water supply 10 bar | 3,883,000 IRR | 10.7 Mm | 5.71 |

| PE pipe 200 Water supply 10 bar | 3,560,000 IRR | 11.9 Mm | 7.05 |

| PE pipe 225 Water supply 10 bar | 4,510,000 IRR | 13.4 Mm | 8.93 |

| PE pipe 250 Water supply 10 bar | 5,555,000 IRR | 14.8 Mm | 11 |

| PE pipe 315 Water supply 10 bar | 8,787,000 IRR | 18.7 Mm | 17.4 |

| PE pipe 400 Water supply 10 bar | 14,140,000 IRR | 23.7 Mm | 28 |

| PE pipe 450 Water supply 10 bar | 17,877,000 IRR | 26.7 Mm | 35.4 |

| PE pipe 500 Water supply 10 bar | 22,119,000 IRR |

29.7 Mm | 43.8 |

| PE pipe 560 Water supply 10 bar | 27,674,000 IRR | 33.2 Mm | 54.8 |

| PE pipe 630 Water supply 10 bar | 35,047,000 IRR | 37.4 Mm | 69.4 |

| PE pipe 710 Water supply 10 bar | 44,490,000 IRR | 42.1 Mm | 88.1 |

| PE pipe 800 Water supply 10 bar | 56,560,000 IRR | 47.4 Mm | 112 |

| PE pipe 900 Water supply 10 bar | 71,205,000 IRR | 53.3 Mm | 141 |

| PE pipe 1000 Water supply 10 bar | 88,375,000 IRR | 59.3 Mm | 175 |

PE pipe gaseous

PE pipe gaseous13.6 SDR

Price of PE pipe gaseousPE pipe gaseous The standard seal and approval of the gas company SDR 13.6 Installment sale with bank guarantee |

|||

| PE pipe gaseous SDR 13.6 | Price per meter | thickness | Weight |

| PE pipe gaseous 63 – SDR 13.6 | 568,000 IRR | 4.7 Mm | 0.873 |

| PE pipe gaseous 75 – SDR 13.6 | 806,000 IRR | 5.6 Mm | 1.24 |

| PE pipe gaseous 90 – SDR 13.6 | 1,151,000 IRR | 6.7 Mm | 1.77 |

| PE pipe gaseous 110 – SDR 13.6 | 1,703,000 IRR | 8.1 Mm | 2.62 |

| PE pipe gaseous 125 – SDR 13.6 | 2,191,000 IRR | 9.2 Mm | 3.37 |

| PE pipe gaseous 140 – SDR 13.6 | 2,743,000 IRR | 10.3 Mm | 4.22 |

| PE pipe gaseous 160 – SDR 13.6 | 3,575,000 IRR | 11.8 Mm | 5.5 |

| PE pipe gaseous 180 – SDR 13.6 | 4,518,000 IRR | 13.3 Mm | 6.98 |

| PE pipe gaseous 200 – SDR 13.6 | 5,564,000 IRR | 14.7 Mm | 8.56 |

| PE pipe gaseous 225 – SDR 13.6 | 7,085,000 IRR | 16.6 Mm | 10.9 |

| PE pipe gaseous 250 – SDR 13.6 | 8,710,000 IRR | 18.4 Mm | 13.4 |

| PE pipe gaseous 315 – SDR 13.6 | 13,780,000 IRR | 23.2 Mm | 21.2 |

| PE pipe gaseous 400 – SDR 13.6 | 22,165,000 IRR | 29.4 Mm | 34.1 |

| PE pipe gaseous 450 – SDR 13.6 | 28,080,000 IRR | 33.1 Mm | 43.2 |

| PE pipe gaseous 500 – SDR 13.6 | 34,645,000 IRR | 36.8 Mm | 53.3 |

| PE pipe gaseous 560 – SDR 13.6 | 43,485,000 IRR | 41.2 Mm | 66.9 |

| PE pipe gaseous 630 – SDR 13.6 | 54,990,000 IRR | 46.3 Mm | 84.6 |

| PE pipe gaseous 710 – SDR 13.6 | 69,550,000 IRR |

52.2 Mm | 107 |

| PE pipe gaseous 800 – SDR 13.6 | 88,400,000 IRR |

58.8 Mm | 136 |

| PE pipe gaseous 900 – SDR 13.6 | 111,800,000 IRR | 66.1 Mm | 172 |

| PE pipe gaseous 1000 – SDR 13.6 | 138,060,000 IRR | 73.4 Mm | 212.4 |

PE pipe gaseous 11 SDR

Price PE pipe gaseous 11 SDRPE pipe gaseous The standard seal and approval of the gas company SDR 11 Installment sale with bank guarantee |

|||

| PE pipe gaseous SDR 11 | Price per meter | thickness | Weight |

| PE pipe gaseous 63 – SDR 11 | 682,000 IRR | 5.8 Mm | 1.05 |

| PE pipe gaseous 75 – SDR 11 | 956,000 IRR | 6.8 Mm | 1.47 |

| PE pipe gaseous 90 – SDR 11 | 1,378,000 IRR | 8.2 Mm | 2.12 |

| PE pipe gaseous 110 – SDR 11 | 2,041,000 IRR | 10.0 Mm | 3.14 |

| PE pipe gaseous 125 – SDR 11 | 2,652,000 IRR | 11.4 Mm | 4.08 |

| PE pipe gaseous 140 – SDR 11 | 3,302,000 IRR | 12.7 Mm | 5.08 |

| PE pipe gaseous 160 – SDR 11 | 4,335,000 IRR | 14.6 Mm | 6.67 |

| PE pipe gaseous 180 – SDR 11 | 5,473,000 IRR | 16.4 Mm | 8.42 |

| PE pipe gaseous 200 – SDR 11 | 6,760,000 IRR | 18.2 Mm | 10.4 |

| PE pipe gaseous 225 – SDR 11 | 8,515,000 IRR | 20.5 Mm | 13.1 |

| PE pipe gaseous 250 – SDR 11 | 10,530,000 IRR | 22.7 Mm | 16.2 |

| PE pipe gaseous 315 – SDR 11 | 16,640,000 IRR | 28.6 Mm | 25.6 |

| PE pipe gaseous 400 – SDR 11 | 26,845,000 IRR | 36.3 Mm | 41.3 |

| PE pipe gaseous 450 – SDR 11 | 33,995,000 IRR | 40.9 Mm | 52.3 |

| PE pipe gaseous 500 – SDR 11 | 41,925,000 IRR | 45.4 Mm | 64.5 |

| PE pipe gaseous 560 – SDR 11 | 52,520,000 IRR | 50.8 Mm | 80.8 |

| PE pipe gaseous 630 – SDR 11 | 66,300,000 IRR | 57.2 Mm | 102 |

| PE pipe gaseous 710 – SDR 11 | 84,500,000 IRR | 64.5 Mm | 130 |

| PE pipe gaseous 800 – SDR 11 | 107,055,000 IRR | 72.6 Mm | 164.7 |

| PE pipe gaseous 900 – SDR 11 | 135,525,000 IRR | 81.7 Mm | 208.5 |

| PE pipe gaseous 1000 – SDR 11 | 167,375,000 IRR | 90.8 Mm | 257.5 |

Standard PE pipe

To download and receive the list of standards related to polyethylene pipes and fittings, follow the link below. We have prepared all the official standards of Iran in PDF files for you.

Types of PE pipes

Polyethylene pipes are one of the types of plastic pipes that are used as one of the best options for transporting liquids and gases. Different types of polyethylene pipes are:

- High pressure polyethylene pipes (HDPE): These types of pipes are used to transport water, gas, sewage and chemicals. These pipes have high resistance to pressure, heat and shock, and due to their high thermal stability, they can be used at high temperatures.

- Medium pressure polyethylene pipes (MDPE): These types of pipes are used to transport gas and water and have high resistance to pressure and corrosion. Also, these pipes have high flexibility and easy installation.

- Low pressure polyethylene pipes (LDPE): These types of pipes are used to transport liquids such as water, oil, gas and chemicals. These pipes have high flexibility and less resistance to pressure and heat.

- Single-walled polyethylene pipes: These types of pipes are used for special applications such as transporting gas, water, and chemicals. These pipes have high flexibility and light weight.

- Multi-layered polyethylene pipes: These types of pipes contain different layers of polyethylene

How to prepare PE pipe?

PE pipe, polypropylene pipe, carrogate pipe, drainage pipe, PE pipe sewer, gaseous, water supply, and various types of tank and PE pipe welding machines are among the products produced in Rotengran Parse. By buying from us, you will have the lowest price of these products and the highest standard in the market with a variety of payment methods and easy purchase methods with free shipping. PE pipe with a variety of production in sizes and grades in high quantities and with safe and fast delivery to all parts of Iran and even overseas delivery as soon as possible is one of the excellent services of Rotengaran Parse PE pipe manufacturer.

The difference between polyethylene pipes PE100 and PE80

| PE100 polyethylene pipes | PE80 polyethylene pipes |

| 10 MPa strength | 8 MPa strength |

| UV resistance | Lack of resistance to ultraviolet rays |

| More density and less thickness | Less density and more thickness |

| Weight lower | Weight higher |

Technical specifications of polyethylene pipes PE100 and PE80

| Pipe properties | PE80 | PE100 |

| Density in (gr/cm^3) | 0.95 | 0.96 |

| Impact test at a temperature of 80 degrees and a stress of 4 MPa | 165 | 500 |

| Crack growth resistance test at 80 degrees | 600 | 1900 |

| modulus of elasticity (mpa) | 950 | 1150 |

| minimum strength (mpa) | 8 | 10 |

| yield stress (mpa) | 22 | 23 |

Table of technical specifications of PE80 polyethylene pipes

| Nominal outer diameter Dn (Mm) | Pipe series | |||||||

| S20 | S16 | S10 | S8 | S6.3 | S5 | S4 | S3.2 | |

| Standard Aspect Ratio (SDR) | ||||||||

| SDR41 | SDR33 | SDR21 | SDR17 | SDR13.6 | SDR11 | SDR9 | SDR7.4 | |

| nominal pressure (PN) | ||||||||

| PN3.2 | PN4 | PN6.3 | PN8 | PN10 | PN12.5 | PN16 | PN20 | |

| wall nominal thickness (mm) | ||||||||

| 16 | – | – | – | – | – | – | 1.8 | 2.2 |

| 20 | – | – | – | – | 1.8 | 1.9 | 2.3 | 2.8 |

| 25 | – | – | – | 1.8 | 1.9 | 2.3 | 2.8 | 3.5 |

| 32 | – | – | – | 1.9 | 2.4 | 2.9 | 3.6 | 4.4 |

| 40 | – | – | 1.9 | 2.4 | 3.0 | 3.7 | 4.5 | 5.5 |

| 50 | – | 1.8 | 2.4 | 3.0 | 3.7 | 4.6 | 5.6 | 6.9 |

| 63 | 1.8 | 2.0 | 3.0 | 3.8 | 4.7 | 5.8 | 7.1 | 8.6 |

| 75 | 1.9 | 2.3 | 3.6 | 4.5 | 5.6 | 6.8 | 8.1 | 10.3 |

| 90 | 2.2 | 2.8 | 4.3 | 5.4 | 6.7 | 8.2 | 10.1 | 12.3 |

| 110 | 2.7 | 3.4 | 5.3 | 6.6 | 8.1 | 10.2 | 12.3 | 15.1 |

| 125 | 3.1 | 3.9 | 6.0 | 7.4 | 9.2 | 11.4 | 14.0 | 17.1 |

| 140 | 3.5 | 4.3 | 6.7 | 8.3 | 10.3 | 12.7 | 15.7 | 19.2 |

| 160 | 4.0 | 4.9 | 7.7 | 9.5 | 11.8 | 14.6 | 17.9 | 21.9 |

| 180 | 4.4 | 5.5 | 8.6 | 10.7 | 13.3 | 16.4 | 20.1 | 24.6 |

| 200 | 4.9 | 6.2 | 9.6 | 11.9 | 14.7 | 18.2 | 22.4 | 27.4 |

| 225 | 5.5 | 6.9 | 10.8 | 13.4 | 16.6 | 20.5 | 25.2 | 30.8 |

| 250 | 6.2 | 7.7 | 11.9 | 14.8 | 18.4 | 22.7 | 27.9 | 34.2 |

| 280 | 6.9 | 8.6 | 13.4 | 16.6 | 20.6 | 25.9 | 31.1 | 38.3 |

| 315 | 7.7 | 9.7 | 15.0 | 18.7 | 23.2 | 28.6 | 35.2 | 43.1 |

| 355 | 8.7 | 10.9 | 16.9 | 21.1 | 26.1 | 32.2 | 39.4 | 48.5 |

| 400 | 9.8 | 12.3 | 19.1 | 23.7 | 29.4 | 36.3 | 44.7 | 54.7 |

| 450 | 11.0 | 13.8 | 21.5 | 26.7 | 33.1 | 40.9 | 50.3 | 61.5 |

| 500 | 12.3 | 15.3 | 23.9 | 29.7 | 36.8 | 45.4 | 55.8 | 68.3 |

| 560 | 13.7 | 17.2 | 26.7 | 33.2 | 41.2 | 50.8 | 62.5 | – |

| 630 | 15.4 | 19.3 | 30.0 | 37.4 | 46.3 | 57.2 | – | – |

| 710 | 17.4 | 21.8 | 33.9 | 42.1 | 52.2 | 64.5 | – | – |

| 800 | 19.6 | 24.5 | 38.1 | 47.4 | 58.8 | – | – | – |

| 900 | 22.0 | 27.6 | 42.9 | 53.3 | 66.1 | – | – | – |

| 1000 | 24.5 | 30.6 | 47.7 | 59.3 | – | – | – | – |

| 1200 | 29.4 | 36.7 | 57.2 | – | – | – | – | – |

| 1400 | 34.4 | 42.9 | 66.7 | – | – | – | – | – |

| 1600 | 39.2 | 49.0 | – | – | – | – | – | – |

Table of technical specifications of PE pipe PE100

| Nominal outer diameter Dn (Mm) | Pipe series | |||||||

| S25 | S20 | S12.5 | S10 | S8 | S6.3 | S5 | S4 | |

| Standard Aspect Ratio (SDR) | ||||||||

| SDR51 | SDR41 | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 | SDR9 | |

| nominal pressure (PN) | ||||||||

| PN3.2 | PN4 | PN6.3 | PN8 | PN10 | PN12.5 | PN16 | PN20 | |

| wall nominal thickness (mm) | ||||||||

| 16 | – | – | – | – | – | – | – | 1.8 |

| 20 | – | – | – | – | – | 1.8 | 1.9 | 2.3 |

| 25 | – | – | – | – | 1.8 | 1.9 | 2.3 | 2.8 |

| 32 | – | – | – | – | 1.9 | 2.4 | 2.9 | 3.6 |

| 40 | – | – | 1.8 | 1.9 | 2.4 | 3.0 | 3.7 | 4.5 |

| 50 | – | – | 2.0 | 2.4 | 3.0 | 3.7 | 4.6 | 5.6 |

| 63 | – | 1.8 | 2.5 | 3.0 | 3.8 | 4.7 | 5.8 | 7.1 |

| 75 | 1.8 | 1.9 | 2.9 | 3.6 | 4.5 | 5.6 | 6.8 | 8.4 |

| 90 | 1.8 | 2.2 | 3.5 | 4.3 | 5.4 | 6.7 | 8.2 | 10.1 |

| 110 | 2.2 | 2.7 | 4.2 | 5.3 | 6.6 | 8.1 | 10.0 | 12.3 |

| 125 | 2.5 | 3.1 | 4.8 | 6.0 | 7.4 | 9.2 | 11.4 | 14.0 |

| 140 | 2.8 | 3.5 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 | 15.7 |

| 160 | 3.2 | 4 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 | 17.9 |

| 180 | 3.6 | 4.4 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 | 20.1 |

| 200 | 3.9 | 4.9 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 | 22.4 |

| 225 | 4.4 | 5.5 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 | 25.2 |

| 250 | 4.9 | 6.2 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 | 27.9 |

| 280 | 5.5 | 6.9 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 | 31.3 |

| 315 | 6.2 | 7.7 | 12.1 | 15.0 | 18.7 | 23.2 | 28.6 | 35.2 |

| 355 | 7.0 | 8.7 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 | 39.7 |

| 400 | 7.9 | 9.8 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 | 44.7 |

| 450 | 8.8 | 11.0 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 | 50.3 |

| 500 | 9.8 | 12.3 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 | 55.8 |

| 560 | 11.0 | 13.7 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 | 62.5 |

| 630 | 12.3 | 15.4 | 24.1 | 30.0 | 37.4 | 46.3 | 57.2 | – |

| 710 | 13.9 | 17.4 | 27.2 | 33.9 | 42.1 | 52.2 | 64.5 | – |

| 800 | 15.7 | 19.6 | 30.6 | 38.1 | 47.4 | 58.8 | – | – |

| 900 | 17.6 | 22.0 | 34.4 | 42.9 | 53.3 | 66.1 | – | – |

| 1000 | 19.6 | 24.5 | 38.2 | 47.7 | 59.3 | – | – | – |

| 1200 | 23.5 | 29.4 | 45.9 | 57.2 | – | – | – | – |

| 1400 | 27.4 | 34.4 | 53.5 | 66.7 | – | – | – | – |

| 1600 | 31.3 | 39.2 | 61.2 | – | – | – | – | – |

List of single wall PE pipe sewer in mm and inches

PE pipe price calculation:

Polyethylene pipes are the most widely used industrial pipes. These pipes have attracted the attention of many industries due to their outstanding features. Like other polymer products, these pipes must be designed and manufactured according to international standards. PE80 and PE100 commercial grade polyethylene pipes are produced in accordance with Iran’s national standard number 14427, Germany’s DIN 8074 standard and ISO 9001 in 2015. The above standards are divided into the most detailed parts; For example, regarding the ISO standard, which is used for the production of PE pipe, several parts have been registered. The different parts of ISO standard include the methods of performing pipe quality control tests, the implementation of pipe burial installation method, PE pipe resistance test, polyethylene pipes and fittings, raw materials and many other cases.

PE pipe price calculation formula

To calculate the price of PE pipe, use the specialized software for calculating the weight and price of PE pipe.

Usage of PE pipe:

Polyethylene pipes are used in many different industries and applications due to their superior physical and mechanical properties. for example:

- Water and sewage industry: Due to their high resistance to corrosion and pressure, polyethylene pipes are suitable for building water and sewage networks in cities, villages and different regions.

- Gas industry: High pressure polyethylene pipes are used to transport natural gas and nitrogen.

- Oil industry: High pressure polyethylene pipes are used as pipelines for oil and gas transportation.

- Electricity industry: Polyethylene pipes are suitable for making electricity cabling pipes due to their high flame resistance.

- Agriculture: Polyethylene pipes are used to transport water and chemicals due to their high resistance to corrosion, wear and pressure.

- Mining: Polyethylene pipes are used to transport minerals in mines due to their high resistance to wear, corrosion and pressure.

- Construction: Polyethylene pipes are used in heating and cooling systems, air conditioning pipes, etc. due to their lightness and easy installation and transportation.

- Automotive industry: polyethylene pipes for engine cooling system, ventilation and…

Benefits of PE pipe

Polyethylene pipes are one of the types of plastic pipes that are used to transfer fluids in various industries. The advantages of using polyethylene pipes are:

1- High resistance to corrosion: polyethylene pipes have high resistance to corrosion. This advantage makes them an excellent choice for applications such as water and wastewater conveyance, wastewater treatment, gas and petrochemicals.

2- High flexibility: Polyethylene pipes have a very high flexibility that allows them to be easily adjusted to any shape and size for your specific use.

3- Light Weight: Polyethylene pipes are very light, which allows you to easily install and transport them.

4- Easy maintenance: Polyethylene pipes require more maintenance and service than metal pipes, when maintenance and repair of pipes is necessary.

5- Environmentally friendly: Polyethylene pipes are environmentally friendly and easily recycled. This advantage has made them a sustainable option for the environment.

6- Easy installation: Polyethylene pipes can be easily installed on different wall or ground surfaces due to their high flexibility.

7- Low cost compared to other types of pipes

Disadvantage of PE pipe

The use of polyethylene pipes in many applications is very common due to their many advantages, such as high resistance to corrosion, pressure, shock, heat and high flexibility. However, some of the disadvantages of polyethylene pipes are:

- Sensitivity to sunlight: Polyethylene pipes are sensitive to sunlight and may dry out and break with prolonged exposure. Therefore, for outdoor use, tubes with anti-UV coating should be used.

- Gas penetration: Polyethylene pipes are sensitive to gases and may be exposed to certain gases, which can lead to problems such as loss of proper pressure inside the pipe or pipe failure.

- Sensitivity to chemicals: polyethylene pipes are sensitive to some chemicals such as alcohols and benzene. If these pipes are used to transport these materials, pipes with special walls must be used.

- Water penetration: Polyethylene pipes can be sensitive to water penetration to certain chemicals and gases, which may lead to changes in their properties.

- Combustibility: Polyethylene pipes can burn against heat and if they are exposed to high heat, they may catch fire and cause damage to the surrounding environment.

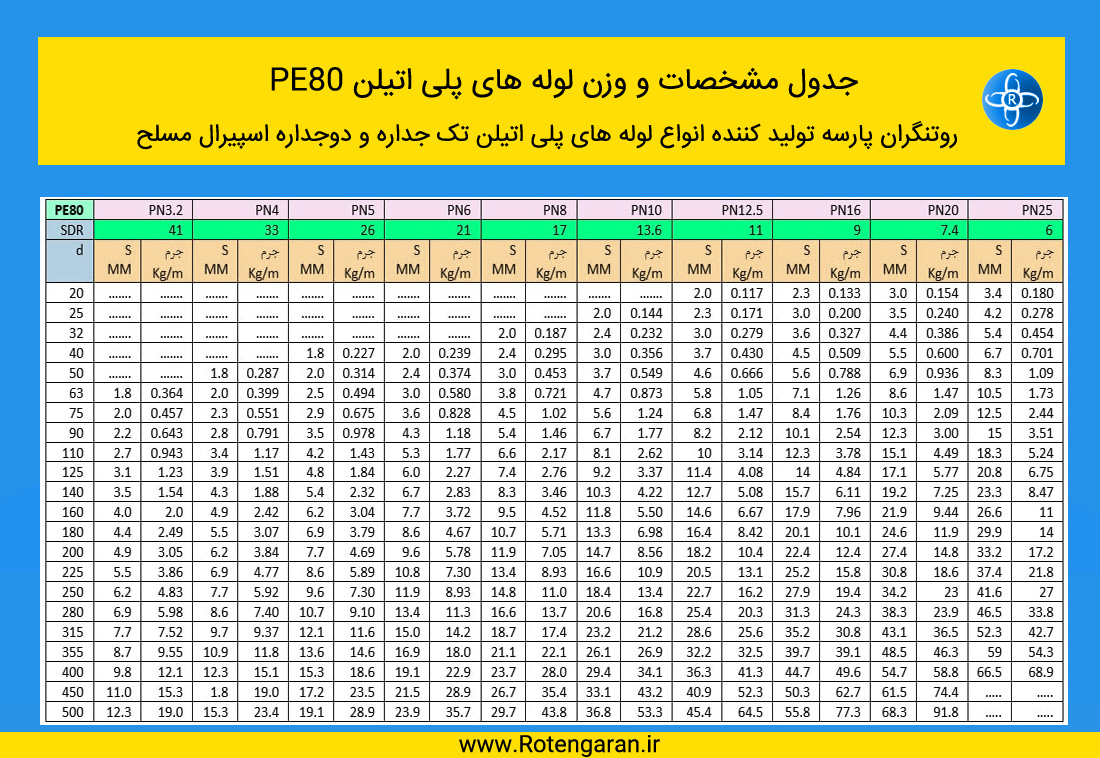

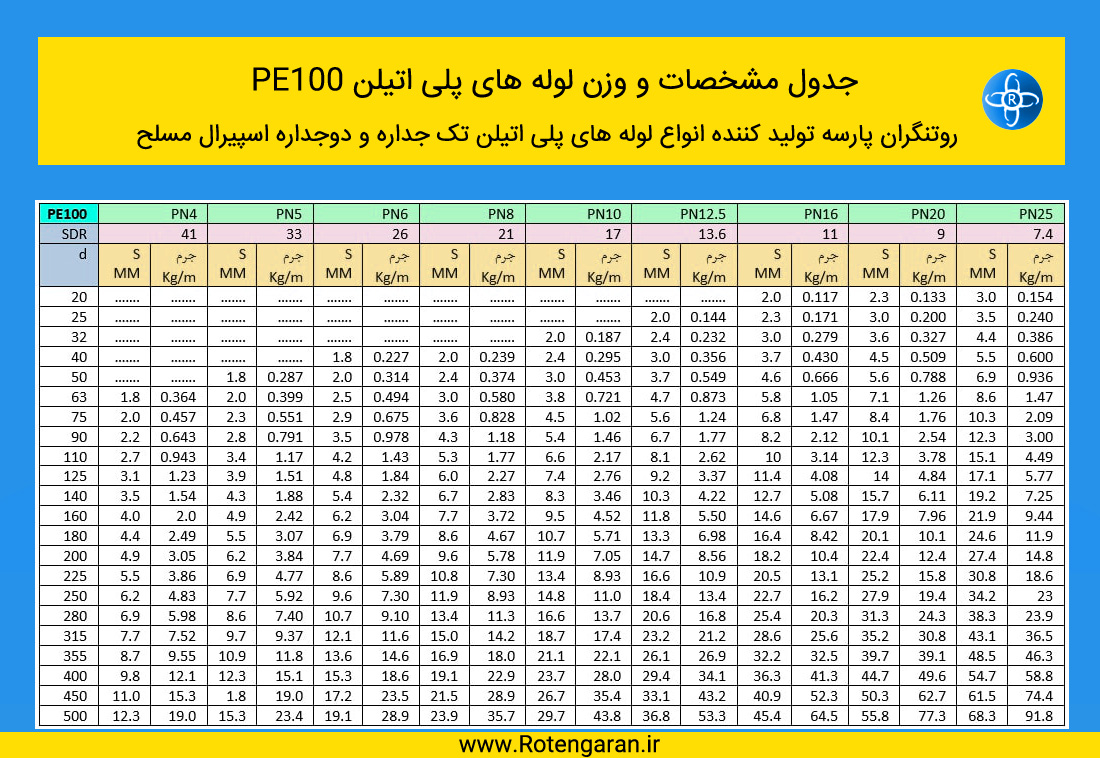

Table of Weight PE pipe

The weight table of PE pipe PE80-PE100 has been set and it is easy to understand the factors that play a role in the price of a PE pipe. In the Weight PE pipe table, there are things such as the inner diameter of the pipe, nominal pressure, working temperature, standard ratio of the pipe unit, mass and safety factor. Each of these factors must be well respected in the production of these plastic pipes. Engineers and PE pipe manufacturers, after designing the production line, adjust all working conditions according to the standard data recorded in these tables. Any inconsistency of the characteristics of the pipes produced in the factory with the data in this table will have a negative effect on the final project. In the following tables, the weight table of polyethylene pipes PE80-PE100, according to the national standard of Iran, are well displayed.

The weight of polyethylene pipes varies based on size, wall thickness, and type of pipe. Below is a table of Weight of some polyethylene pipes in different sizes:

| Pipe size (outside diameter) | wall thickness | Weight for each meter length |

| 20 Mm | 2 Mm | 0.124 kg |

| 25 Mm | 2.3 Mm | 0.177 kg |

| 32 Mm | 3 Mm | 0.308 kg |

| 40 Mm | 3.7 Mm | 0.472 kg |

| 50 Mm | 4.6 Mm | 0.735 kg |

| 63 Mm | 5.8 Mm | 1.165 kg |

| 75 Mm | 6.8 Mm | 1.650 kg |

| 90 Mm | 8.2 Mm | 2.377 kg |

| 110 Mm | 10 Mm | 3.637 kg |

| 125 Mm | 11.4 Mm | 4.566 kg |

| 140 Mm | 12.7 Mm | 5.661 kg |

| 160 Mm | 14.6 Mm | 7.446 kg |

| 180 Mm | 16.4 Mm | 9.416 kg |

| 200 Mm | 18.2 Mm | 11.605 kg |

Table of specifications and weight of PE100 and PE80 pipes:

In what grades can PE pipe be produced?

Polyethylene pipes are graded according to the type of machines and laboratories equipped and the type of consumables in the pipe and fittings association, and PE pipe is produced and supplied based on A-B-C grade. The pipes that are known as grade 1 – grade A – standard are produced with European machines and the consumables are from the first grade materials of Shazand, Amirkabir or Jam petrochemicals. Grade 1 – Grade A – standard pipes are used in the transmission network, agriculture systems and gas supply networks. Non-standard grade B pipes cannot be used with Chinese machines and first grade consumables. Grade B pipes are used in agriculture networks. Grade C pipes, which can be produced with Iranian or Chinese machines, and also new and recycled (combined) materials are used in it. Polyethylene pipes in grades PE80-PE100 are produced in the production unit according to the type of material. PE100 grade is used in gas supply and water supply networks. PE80 grade is used for transmission networks and agriculture systems and telecommunication cable sheaths. Due to the molecular density, PE100 grade has a lower thickness and weight and has a suitable pressure tolerance. Pipes are produced and supplied in branches of 6, 12 and 5.13 meters. Carrogate pipe in different models is one of the other products made in Rotengran, Parse, which is produced and supplied in the models of double-walled polyethylene carrogate pipe, spiral double-walled polyethylene carrogate pipe, reinforced spiral double-walled polyethylene carrogate pipe, and polyethylene tubes. .

Why is black color used in polyethylene pipes?

Polyethylene pipes are usually produced and supplied in black color. Polyethylene materials produced in petrochemicals are either natural or black. The best type of material is the color itself, in which the soot is appropriate and the mix is accurate. In natural pipes, soot or black masterbatch should be added to it. The black color in polyethylene pipes is Anti UV, which increases the resistance of the pipe against ultraviolet rays.

Why is PE pipe Rotengaran Parse?

- Manufacturer of polyethylene pipes with domestic and international ISO standards and production technology in Germany

- Certified and approved by the Ministry of Jihad, Agriculture, Water, Soil and Wastewater

- It has the quality rating of grade A polyethylene products

- The largest and most reliable producer of polyethylene pipes in Iran

- Laboratory of Rotengran Parse Company, a partner and benchmark of the country’s standard department

- The country’s top exporter for three consecutive years

- Valid warranty and insurance policy for pipes from Iran Insurance Company

- Commitment to quality and after-sales service and customer orientation

- Variety of production in single-walled and double-walled polyethylene pipes of Carogate

- Special and different conditions for representatives of Rotengran Parse company

To receive advice, invoice, price list with the number:

Telefax (special line): +982144106256

Telefax (special line): +982632701094

Engineer Mohammad Reza Azizi (CEO): +982144106256

Engineer Mahmoud Esadi (sales manager): +989121249231

Email: Rothengaran@gmail.com

In order to export PE pipe, you can refer to Rotenplast website under Rotengran Parse Holding and get in touch with our experienced consultants.

Frequently Asked Questions:

PE pipe price inquiry

درخواست قیمت

( استعلام قیمت ) جهت دریافت مشاوره و قیمت فرم را کامل کنید مدیران فروش روتنگران پارسه با شما در تماس خواهند بود.